Tire Balancing Manassas VA

Tire Balancing

There is a widespread belief among many car owners that holds: All that’s required to prolong the life of tires is to simply keep them properly inflated, periodically rotate the wheel, and occasionally get the car aligned. While performing these three maintenance requirements does indeed help, one key component is missing – tire balancing.

Many people overlook balancing thinking that the wheels will remain balanced until they’re replaced. However, after being used for tens of thousands of miles, over uneven road surfaces and with various loads and forces continuously acting upon them, tires do develop uneven tread wear patterns. This wear ultimately changes the weight of the rotating mass and, therefore, the balance of the wheel. Even if you can’t feel the vibrations, they are present.

For those who still think tire balancing isn’t important all, consider some recent trends in the automotive industry. The obvious fact that vehicles nowadays are being made lighter is possibly the most compelling argument for precision balancing. Heavier cars made in the past have helped smooth out the ride by dampening numerous vibrations before they could be felt by the driver. Tire technology is another factor. Lower profiled tires are commonly used in today’s style and performance-oriented market; it is more responsive and gives the driver enhanced road feedback. In effect, the slightest imbalance can be sensed in most modern vehicles. For vehicles with plus-sized tires and wheels, balancing is even more important.

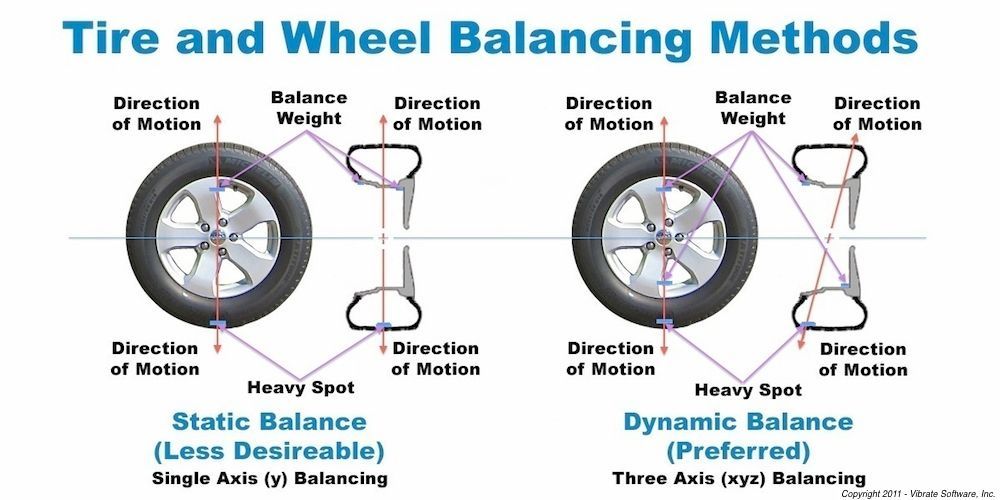

When a new tire is installed or an older tire is remounted onto a rim, an assembly weighing forty pounds (on average for cars) is formed from two slightly flawed units. It is virtually impossible for this assembly to have specific weight distribution about its radial and lateral centers. These imperfections, in turn, create two types of imbalance: static and dynamic – although most wheels have a combination of both types of imbalance. Static imbalance happens when there is a heavy or light spot on the tirewheel combination which doesn’t roll evenly. The static imbalance creates a hop or vertical vibration. One solution to resolving this problem is to use a “bubble balancer” which is a fairly inexpensive device that uses a bubble level as an indicator.

On the other hand, dynamic imbalance happens when there is uneven weight on one or both sides of the wheel assembly’s lateral centerline, thus creating a side-to-side shimmy. The dynamic imbalance generate a wobbling vibration that can be corrected by using a technique referred to as “spin balancing.” This can be done either on or off the vehicle, though the vast majority of wheels are balanced off the car on computerized spin balancers.

On rare occasions, however, a tire may be manufactured with slightly inconsistent sidewall stiffness, creating what is called force variance which leads to an imbalance problem. There is a new generation of balancers that can detect this condition and guide the technician to remount the tire in an optimum position that puts the assembly within specification and eliminates the problem. We use a computerized wheel balancer by Bosch that not only solves balance and eccentricity-based vibration problems, but also “road tests” the wheel before it’s remounted on the vehicle. It places a load on the tire as its being balanced thereby verifying if the assembly is “round when rolling.” CoHo Auto uses only Bosch equipment since there are no better machines on the market to correct wheel balance/anomaly problems.

These machines can even distinguish between tire and rim run-out to support optimum mounting. Wheels are marked to identify the minimum radial run-out spot (low point) on the bead seat surface while tires are marked with a high point location. Mounting the assembly to match these two points is called match mounting. This method minimizes the balance weight needed to correct any remaining imbalance and the radial run-out that may occur in the wheel/tire assembly. And because many of today’s wheel designs necessitate unique wheel weight placement to obtain both precise balance and esthetic appeal, wheel weight placement can also be achieved through these machines.

At any rate and regardless of which wheel balancing system is used, a technician is directed to place counter weights on the rim’s outer surface to offset the imbalance. When the balancing system corrects the problem, the wheel is said to have an ideal weight distribution and will not vibrate. But as pointed out above, tires wear and as a result, they become out-of-balance again.

Imbalance is a key component in tire wear but can easily be corrected by static, dynamic and road force balancing. Considering what it costs to replace tires, periodically rebalancing tires is a prudent preventative measure.